The news that Idemitsu Kosan has broken ground on a large-scale solid electrolyte pilot plant with Toyota feels like one of those quietly important moments that rarely make big headlines — yet could reshape the EV industry over the next decade. For years, solid-state batteries have lived in the space between promise and patience. This move suggests that promise is finally starting to harden into reality.

Idemitsu’s decision to greenlight the project comes after two smaller demonstration facilities delivered encouraging results. That progression matters. It signals that the technology has moved beyond lab-scale curiosity and into something that can be produced, tested, and refined at industrial volumes. The new pilot plant, scheduled for completion by the end of 2027, will produce solid electrolytes specifically for Toyota’s all-solid-state EV batteries — the heart of what many believe will be the next major leap in electric mobility.

Toyota’s timeline is equally telling. The automaker is targeting 2027–2028 for the first EVs equipped with all-solid-state batteries, albeit in limited volumes at first. That cautious rollout reflects both ambition and realism. Scaling a fundamentally new battery architecture is enormously complex, but Toyota has never been a company known for rushing unproven tech to market.

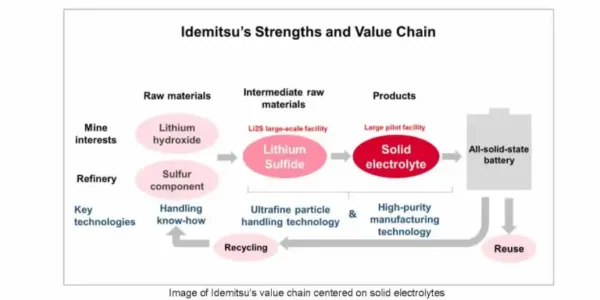

What makes this effort stand out is the ecosystem behind it. Alongside Idemitsu, Toyota is working with Sumitomo Metal Mining, which has developed a highly durable cathode material using proprietary powder-synthesis technology. Backed by approval from Japan’s Ministry of Economy, Trade, and Industry, the project has clear institutional and industrial momentum.

The numbers, while still aspirational, are hard to ignore. Toyota previously showcased a solid-state battery prototype capable of up to 1,200 km of range and charging in under 10 minutes. Even if early production falls well short of that benchmark, the advantages — higher energy density, faster charging, improved safety — could fundamentally change how consumers think about EV ownership.

In my view, this pilot plant is less about hitting headline specs and more about credibility. Toyota and Idemitsu are signaling that solid-state batteries are no longer just a future concept, but a technology entering its most difficult and most important phase: industrialization. If they succeed, this could mark the beginning of the post-lithium-ion era for electric vehicles.